SY-Z-(2-3.5) type flotation column

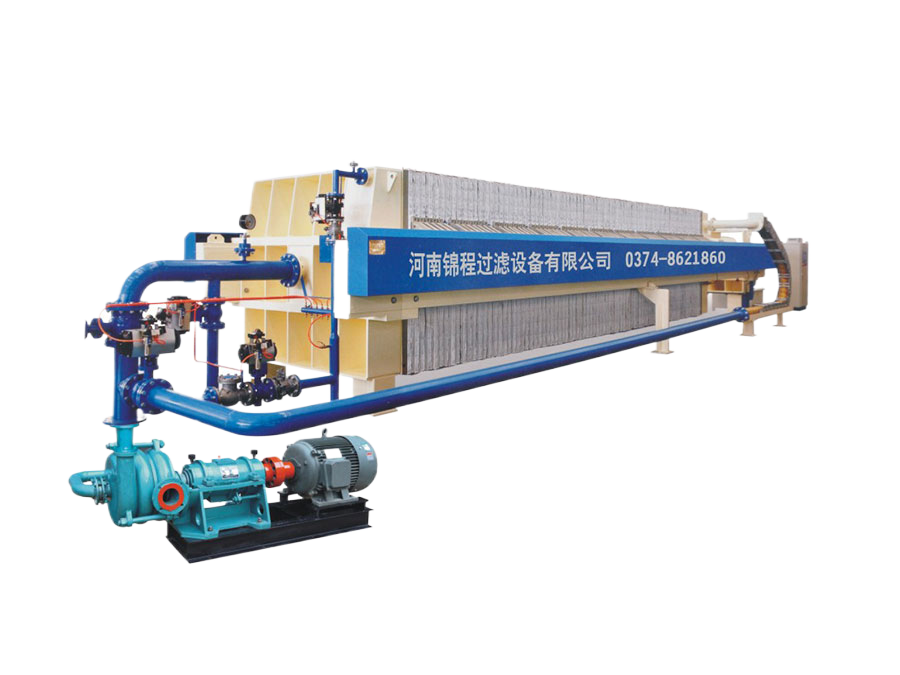

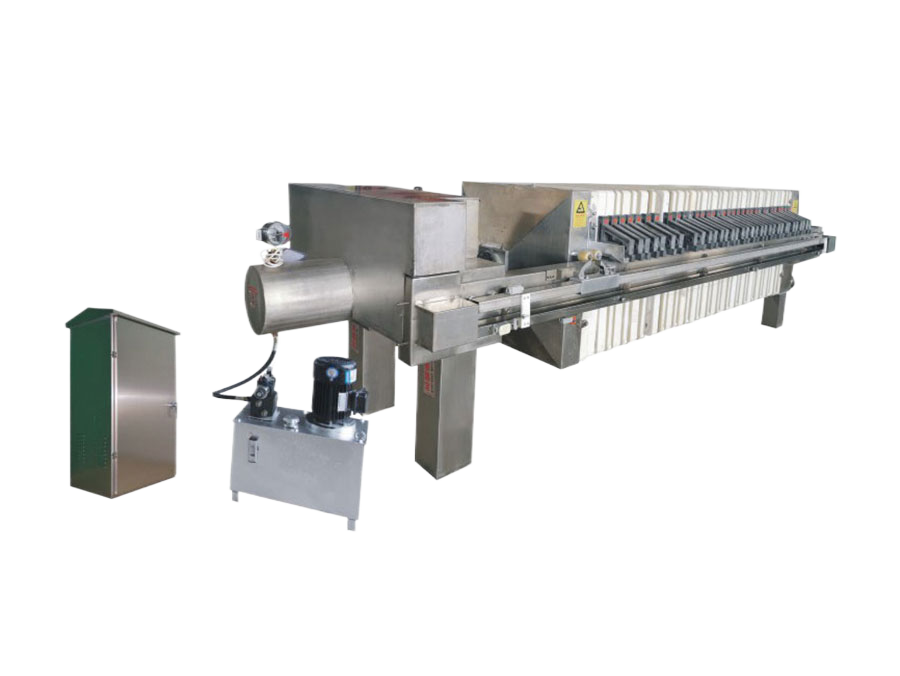

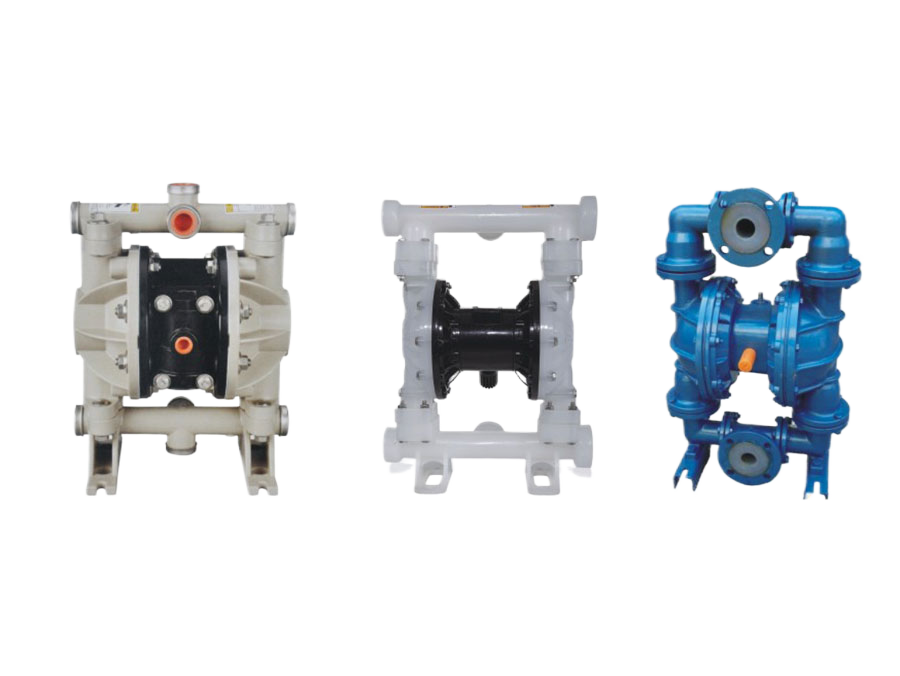

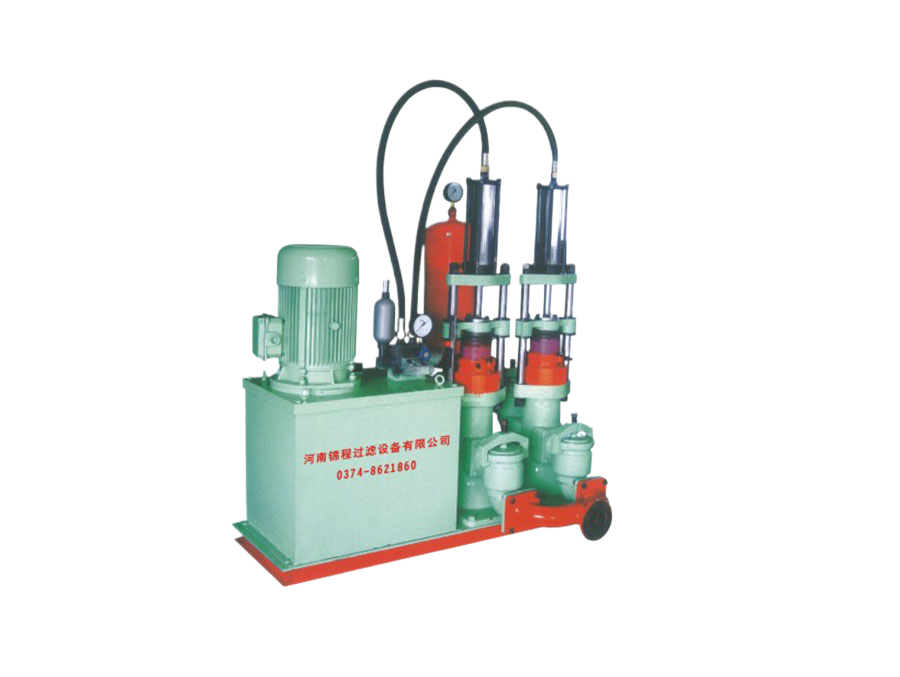

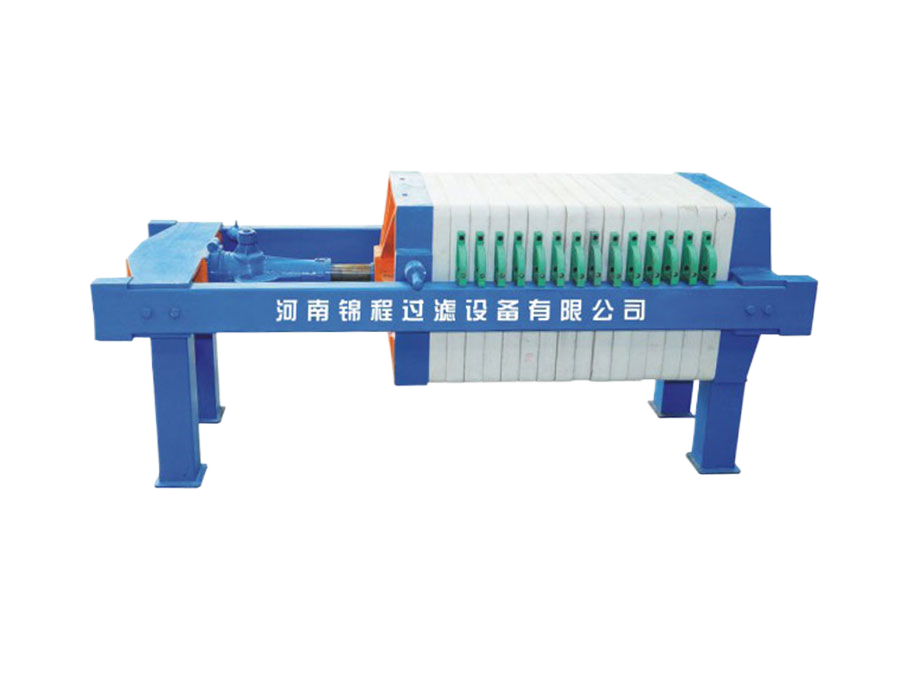

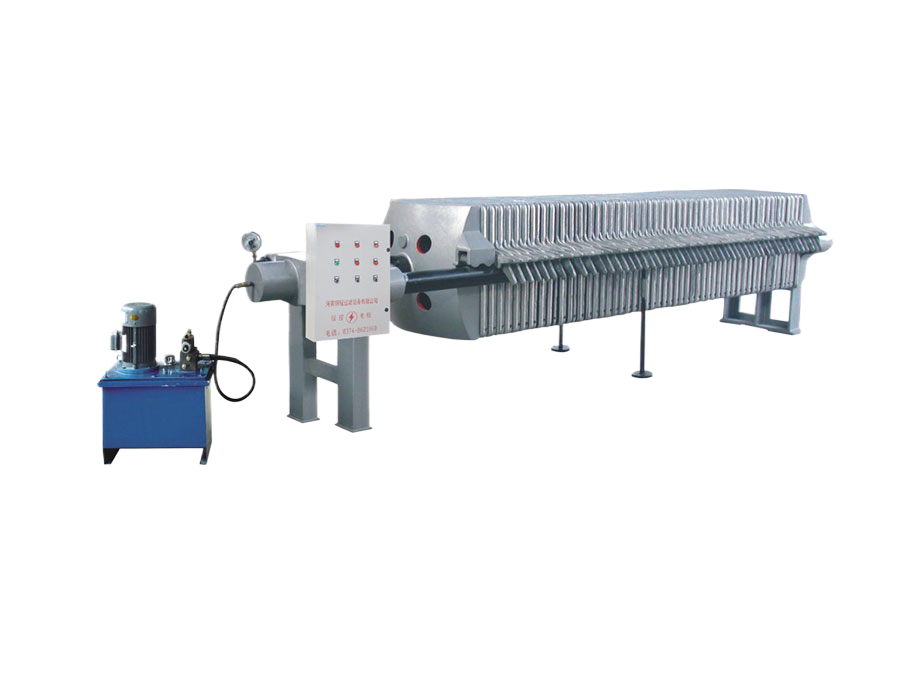

Belonging category: Filter press complete set of optional equipment

Product Details

Product introduction and use

Water-pressure self-priming air high-efficiency and energy-saving flotation column is a new type of high-efficiency and energy-saving flotation machine developed by our company. This series of products comprehensively utilize the advantages of similar products at home and abroad in terms of appearance design and internal structure, and make innovation and improvement to make the performance of the equipment more perfect. The water-pressure self-priming air-efficient and energy-saving flotation column has the advantages of high efficiency, energy saving, less land occupation, small investment, quick effect, long service life, fast flotation speed, large processing capacity, and easy maintenance.

The comprehensive performance of the water-pressure self-priming air high-efficiency and energy-saving flotation column is currently at the forefront of the country. It can be used for particle and slime flotation below 0.5mm, and is widely used in large, medium and small coal preparation plants for slime recovery and beneficiation.

Working principle and technical characteristics

The working principle of the water-pressure self-priming air high-efficiency and energy-saving flotation column: the slurry-adjusted slime water is fed into the slurry distributor by the feed pump under a certain pressure, and then the slurry is evenly distributed into each mineralizer, so that the flotation agent and slurry self-absorb air and fully mineralize bubbles. After the slurry enters the foaming device, the pressure decreases sharply, and a large number of bubbles occur, so that fine hydrophobic fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine fine, as the bubbles rise to the surface of the pulp and are discharged into the concentrate tank, other hydrophilic, high-ash minerals sink to the bottom of the barrel with tailings after automatic circulation flotation. Separation of high ash products from low ash products is thereby achieved.

Technical features

1. The advanced self-suction jet high gas dissolution mineralization technology is adopted, which has good mineralization effect and high selectivity.

2. A series of sorting processes such as feeding, aeration, mineralization and foaming of the flotation column are completed by a feeding pump to achieve the purpose of energy saving.

3. External slurry aeration system, easy to maintain and replace.

4, low energy consumption, installed and actual power consumption are lower than similar flotation machine.

Equipment structure and process

The water-pressure self-priming air high-efficiency and energy-saving flotation column is composed of slurry barrel or slurry tank, reagent barrel, special feed pump, slurry distributor, mineralizer, sorting barrel, concentrate tank, tailings collection tank and tailings box.

Key words:

Filtering equipment

Previous article: SGN-3.5 deep cone high efficiency thickener

Next article: Circular mud filter 1

Product Consulting

Leave your contact information to get a free product quote