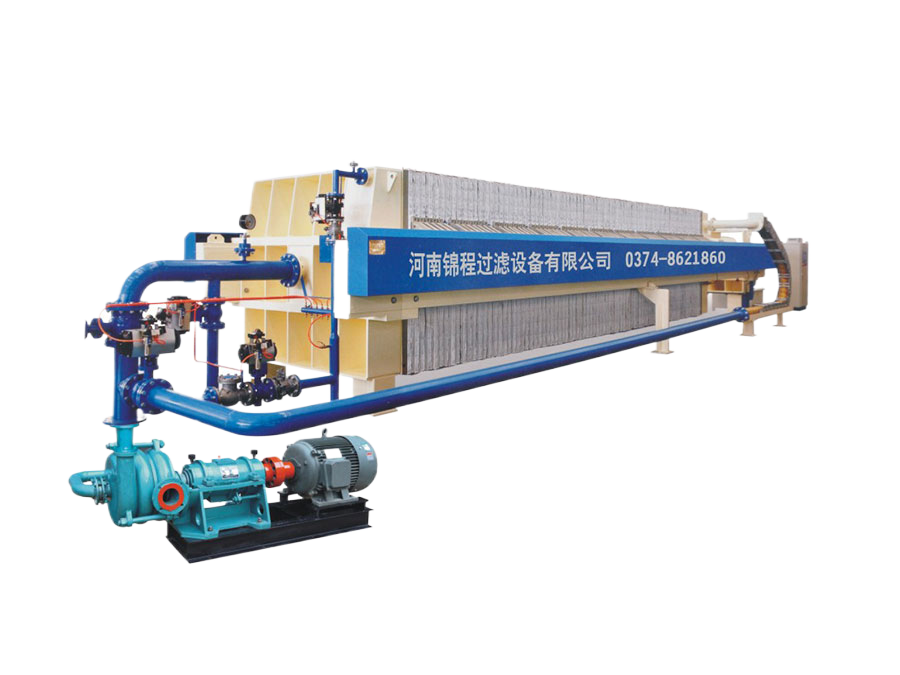

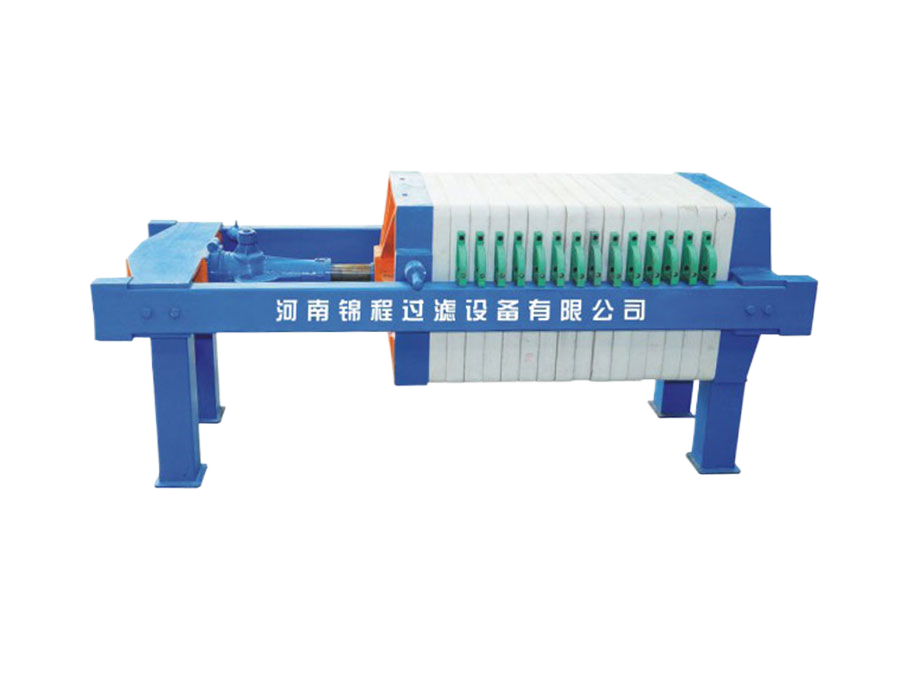

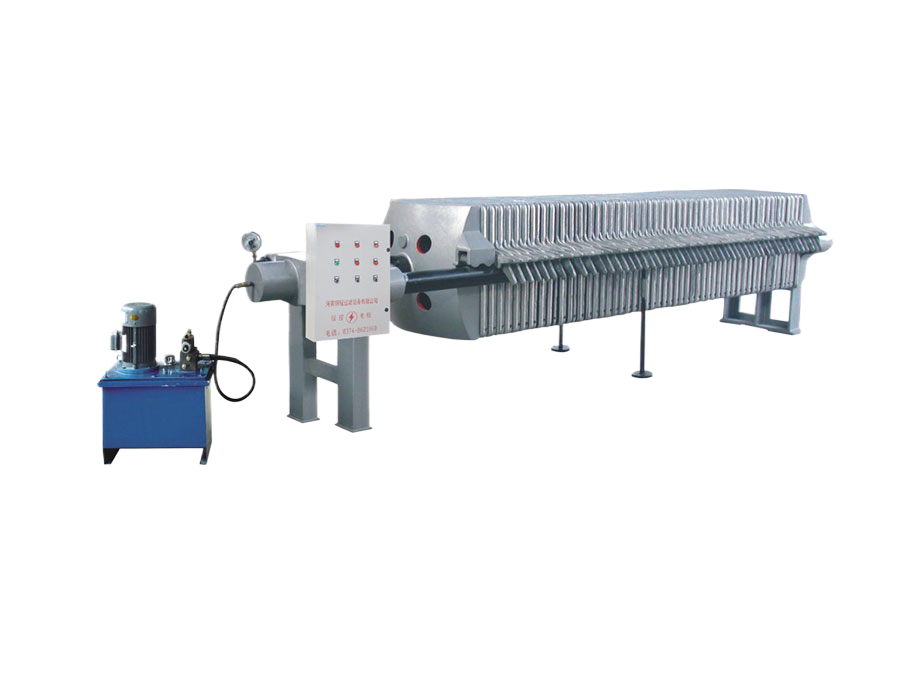

Program-controlled filter press machine for automatic conveying of filter cake

Belonging category: Filter press

Product Details

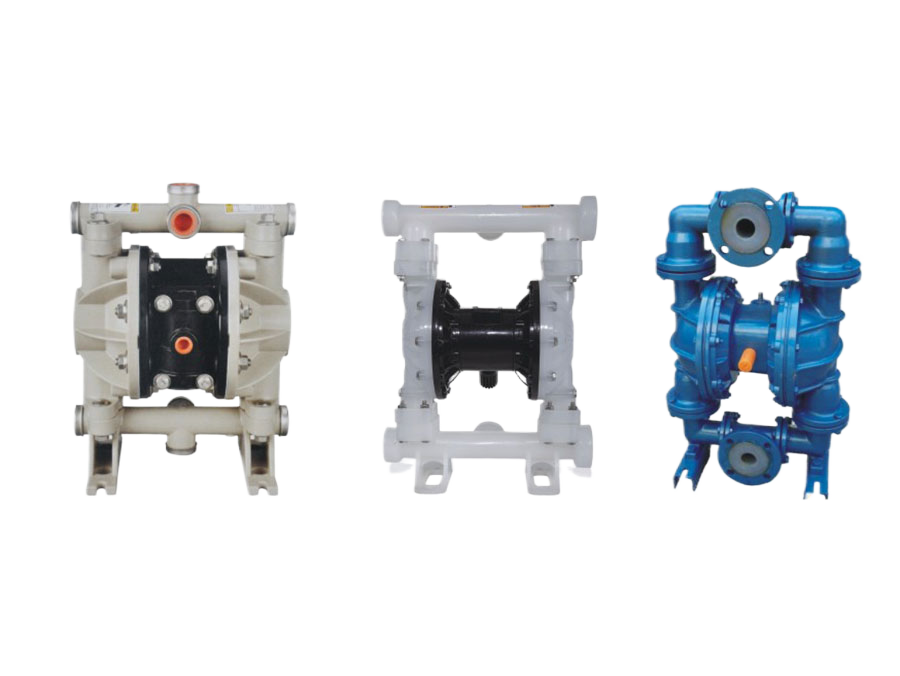

The membrane filter press consists of a membrane plate and a chamber plate, which are arranged to form a filtration chamber. Under the pressure of the feed pump, the slurry will enter the filter chamber, and the solid and liquid are separated by the filter medium (filter cloth). After the solid forms a cake, air or high-pressure water will enter the inner layer of the diaphragm, fully squeeze the middle cake, reduce the water content, and facilitate removal. For the filtration of viscous materials and the high requirements for the final moisture content, the machine has its own unique effect.

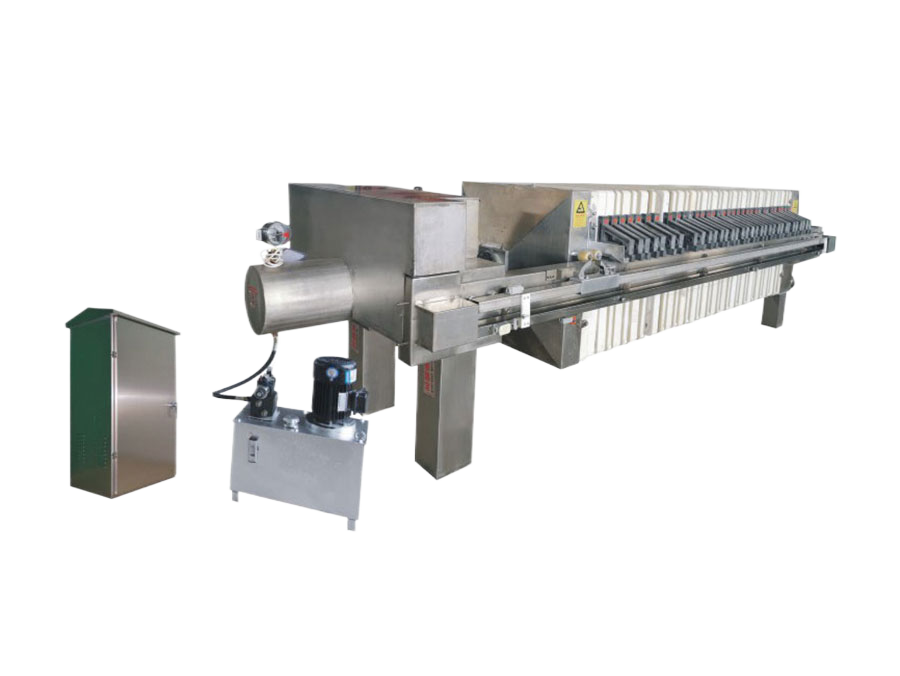

The filter plate is molded by reinforced propylene. The diaphragm plate and the polypropylene core plate are thermally combined, which is strong and durable, not easy to fall off, and has a long service life.

The equipment adopts the functions of automatic pressure maintaining, automatic plate shifting system, program-controlled quick opening, etc. The operation is simple, safe and labor-saving. Continuous action can be realized through the buttons on the operation control panel. The control panel is equipped with various safety devices to ensure the operator The safety and the normal operation of the filter press.

Key words:

Filtering equipment

Previous article: All-inclusive stainless steel automatic pull plate filter press

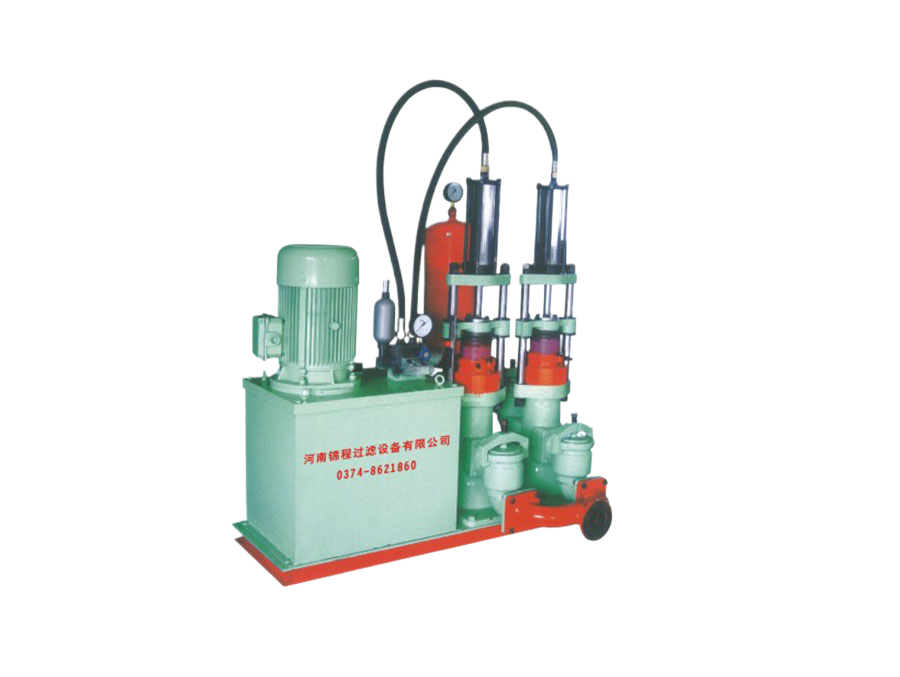

Next article: Jack pressing filter press

Product Consulting

Leave your contact information to get a free product quote